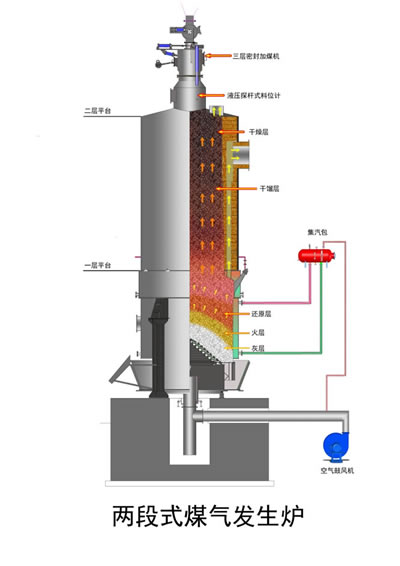

KW3M Two-stage gasifier

The two section gas producer for production company (also known as the double stage coal gasifier, coal gasification) is dedicated to the design of the furnace type, can be in coal by light tar distillation section distillation, gas calorific value than that of KW1M (Duan Lu) series of high environmental protection, more reliable. Is the state Chang and promotion of furnace type.

The cross-sectional area of the dry distillation section is large, the amount of coal storage, coal seam down slowly, carbonization time is longer, so the coal to be fully dry distillation; distillation section in the way of heat transfer is mainly convective heat transfer; simple structure, convenient repair; less investment.

Structural characteristics

Coal feeding: a practical and reliable coal level detector cooperates with stoker complete automatic coal filling, ensure full feed operation.

Pyrolysis: lining lining, this structure by strict heat transfer and heat exchange calculation and design, can improve the heat transfer efficiency of the coal gasification, after sufficient and effective drying, dry distillation, the volatile increase gas caloric value, but also conducive to the lower section of the coal gasification.

Gasification: the water jacket structure, self-produced vapor is used for gasification.

Feeding mechanism: the drum in advanced plate down bell jar feeding mechanism, has the characteristics of simple operation, convenient maintenance and good air tightness.

The cleaning mechanism: the ratchet pawl, hydraulic drive from both sides of ash, dust knife with a self-designed plough type ash knife, stable and reliable transmission, ash smoothly, I plough the ash knife worked on a variety of domestic and imported generator used by users.

KW3MTwo stage gasifier technology parameters

| Name |

Unit |

Gas generator specifications |

| 2. |

2.2. |

2.4. |

2.6. |

3. |

3.2. |

3.4. |

3.6. |

| Model |

|

KW3M 2 |

KW3M 2.2 |

KW3M 2.4 |

KW3M 2.6 |

KW3M 3 |

KW3M 3.2 |

KW3M 3.4 |

KW3M 3.6 |

| The chamber diameter |

Mm |

2000 |

2200 |

2400 |

2600 |

3000 |

3200 |

3400 |

3600 |

| For fuel |

|

Weakly caking coal, non caking coal and long flame coal |

| Fuel particle size |

Mm |

25-50 25-80 1325 2580 Anthracite bituminous coal |

| The largest coal consumption. |

Kg/h |

600-800 |

Grams |

9001400 |

13001800 |

18002200 |

22002500 |

23002800 |

2500-3000 |

| Gasifying agent |

|

Air steam |

| Gas production |

Nm3/h |

2000-3000 |

23003200 |

29004500 |

41005500 |

6000-7000 |

7000-8000 |

8000-9000 |

8500-10000 |

| Gas calorific value |

KJ/Nm3 |

More than 6070 |

| The gas outlet temperature |

The upper |

C |

80-120 |

| The next section |

C |

400-600 |

| The gas outlet pressure |

The upper |

Pa |

1000-1500 |

| The next section |

Pa |

14701960 |

| Saturation temperature |

C |

50-65 |

| Load of equipment |

T |

70 |

75 |

85 |

95 |

110 |

130 |

150 |

180 |

| Reference size |

H1 |

M |

5.5 |

5.5 |

5.5 |

5.5 |

5.5 |

5.5 |

5.8 |

5.8 |

| H2 |

M |

9.5 |

9.5 |

11.5 |

11.5 |

11.5 |

11.5 |

11.8 |

11.8 | |