Applicable scope:

Suitable for purification, desulfurization of coal gas or city gas (remove the H2S)

The characteristics of:

The gas purity can be adjusted according to actual needs, can smooth control of H in gas2The content of S.

1 compared with the dry desulfurization, the operation cost is lower, to avoid the dry flue gas desulfurization system caused by the desulfurization effect of the regenerated sorbent and adsorption of sulphur and other reasons to increase the cost of production problems.

2 compared with other wet desulfurization, with stable operation, safe operation, high desulfurization efficiency characteristics. The desulfurization efficiency can reach above 97% after desulfurization gas by H2The content of S <50mg/Nm3.

Process:

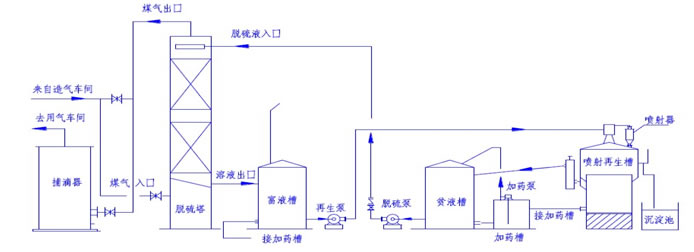

Containing H2S gas enters from the lower part of the desulfurization tower, in the packing layer and the spray tower desulfurization lean liquid reaction, H2The absorption of S removal, discharge the purified gas from desulfurization tower, and then sent to the workshop in the drop catcher in the removal of excess water. The absorption of H from solution under the tower2S into the analysis of sulfur rich liquid, then the regenerative pump to jet regeneration tank and air oxidation reaction, solution and regeneration after liquid level regulator into the lean liquid after desulfurization pump into the desulfurization tower, continuous desulphurization. At the same time slot jet generated sulfur foam overflow to the bubble pool filter, filter out sulfur ointment.

Wet desulfurization.

|