|

Tangshan City Shengda steel is a H type steel, I-beam, channel steel products Co. ltd.. The company determined to create the national steel industry steel carrier. The design annual production capacity of 800000 tons, become the production base of large and medium-sized profiles.

The company has completed the first phase of the project is a Phi 1000 two roller reversible billet mill, mill has six phi 970/ Phi 660 compact universal mill and two for 560 edge rolling machine. The two phase of the project will eventually form the two roller mill seven universal mill and three frame edge rolling machine and a frame, to create the conditions for the production of thin H steel. This is the production line in the domestic three experts enjoy allowance of the State Council led to complete. The long, long rolling cooling, long straightening, cold sawing of world advanced production technology scale. Universal mill is an international advanced level in domestic and imported several digestion based on universal rolling mill, and has adopted the world leading level of domestic research results, and in Tianjin the company developed in cooperation with the world's advanced level. Rolling and cooling control technology of finishing mill using universal method instead of pass method, improve the product dimensional accuracy and mechanical properties. Finishing equipment with variable pitch straightening machine and constant power speed cold sawing machine. The cooling bed for spray cooling of advanced technology. Full automation automatic control.

Product outline: the main steel is carbon steel, low alloy steel, low alloy steel, bridge and hull structural steel, weathering steel. Thin walled H steel: 200*200~500*200mm, web and flange thickness of the thinnest of up to 3.2mm; the standard H type steel: 200*200~500*200mm; 30a-56c: 30a-40c; Channel: i-beam. The product length is 6-18 meters.

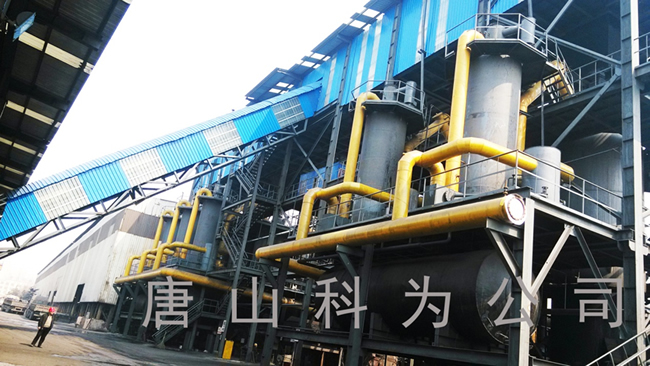

In 2014 August, the Tangshan Department of Industrial Technology Co., Ltd and Tangshan Shengda Steel Co. Ltd. agreed, for the construction of 5 sets of two stage gasifier project. The production and installation of debugging smoothly, by the end of 2014 and put into use. |