|

0Introductions to the.

Our country is one of the world's coal reserves are more abundant country, coal accounted for 92.94% of fossil energy reserves in our country, coal gasification as a kind of clean coal technology, conforms to our country's energy security strategy, including atmospheric fixed bed gasification technology, its production scale, cost of investment, construction cycle, conform to the majority of metallurgy, chemical industry, building materials and machinery industries such as gas, especially the application of the two sections of gas producer more extensive.

In terms of generator gas station, waste water containing phenol has been the problem of the development of environmental protection, many experts after long-term research and exploration, the steam chemical removing phenol method, removing phenol method, burning method, solvent extraction method, resin removing phenol method, sulfonated coal adsorption method, biochemical method and so on dozens of phenol water treatment, use experiment has undergone quite a time, although fumbling their some effective processing method, also has obtained the certain effect, but many serious deficiencies exist various methods respectively, finally had to abandon.How to take effective measures, phenol wastewater thoroughly, and about the survival and development of gas generator.

1The gas station of wastewater containing phenol

1.1Gas station process

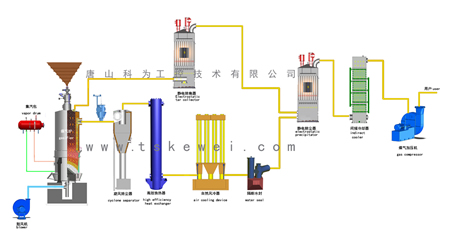

Two sections of gas generator furnace outlet gas temperature is higher, impurity content more, need after purifying, cooling, conveying to the gas lit with, figure 1 for environmental protection and energy-saving technology in the two paragraphs furnace coal gas station, gas in the upper left after the gas stove JiaoQi and electrostatic JiaoQi removal, remove carry tar and dust, coal gas under the gas after the cyclone, heat exchanger and air cooling equipment, dust removal, cooled and the period of the gas mixture.Cooler between mixed gas by electrostatic precipitator and deep processing, such as removing the gas of tiny dust and tar, and condensation of phenol wastewater and a small amount of light oil, and finally the gas pressurization system, to the point of gas.

figure1Two sections of gas producer (environmental protection energy-saving) process flow in the cooled coal gas station

Chart1 process flow of double stage clean gas station (environmental protection technology)

1.2The source of the gas station wastewater containing phenol

1.2.1Water into the item

(1) the water in the coal

Based on its state, the moisture in coal can be divided into two kinds of free water and crystal water, free water and "external water" and "internal moisture", "external water" are greatly influenced by the outside humidity environment.Free water in 105-110 ℃ or so commonly, after 1 to 2 h dry to escape from the coal, and decomposition of above 200 ℃ usually take crystallization water to precipitate.Free water in the coal and water of crystallization in two sections of gas producer of carbonization precipitation was dry, upper mixed in the gas in gaseous form.

(2) the water in the gasification agent

Water vapor as part of the gasification agent, most of which involved in coal gasification reaction to generate combustible material H2, the other part was not involved in the reaction, while the part of coal, hydrogen will be conerted to water in the reaction process, from the basis of the overall results of gasification, general will participate in coal gasification reaction to generate combustible material H2 water vapor, and the ratio of amount of water vapor in the gasification agent called steam decomposition rate.Thus it can be seen that excessive amounts of water vapor in the gasification agent, will cause the loss of steam decomposition rate, increase of water content in gas.

(3) the ground fire, DaQian operation into the water

The normal fire detecting of gas producer and accident DaQian operation process, the general first formed by about 0.3 MPa steam seal, prevent the gas within the furnace, the part of the steam is mixed in the gas, fire or the longer DaQian, gas in water.

(4) the ash tray water seal into the water

Wet ash producer gas generator, ash tray in using water seal at the bottom of the furnace gas and separated from the outside world.High temperature ash fell into the water, will be part of the water into steam into the furnace, thus increasing the gas water content.

(5) the gas water seal into the water

In the generator gas station, to compare the safety, convenient and the isolation of the outside world and the system of gas, in the part of the equipment or gas, often set the number of water seal, when high temperature gas over the water surface, will be part of the water into steam, mixed in the gas.

1.2.2The new presence of water

(1) in the coal tar get out of the water

Two paragraphs furnace in furnace outlet gas temperature control in commonly 80-120 ℃, parts of the gas water exists in the form of liquid droplets, in the period of primary gas purification system, further reduce the gas temperature, increase the water droplets in the gas, and arrested with tar, mixed in the tar.

(2) between the gas condensate cooler places

Mixed gas, two furnace top and bottom sections in the gas cooler between deep purification of cooling system, the indirect heat exchange with the cooling water, the gas is cooled to 35 to 45 ℃, parts of the gas water condensation precipitation, then the gas in the saturated state.

(3) the gas drainage pressure machine

In gas pressurization system, with the increase of gas pressure, the more water vapor partial pressure in gas, the gas saturation is damaged, parts of the gas water precipitation, precipitation water part of the drainage system ruled out by the gas pressure machine, has not been ruled out of water in the form of droplets with the gas into the gas pipeline.

(4) gas pipeline condensation water

A setting in the gas pipeline number of drainage device, in the vent water drainage device consists of two parts, one is the precipitation in the gas pressurization system but not clean water, the other part is in the process of delivery, gas cooling or by external environment and the gas pipeline caused by friction and condensation part of the water droplets.

(5) the final gas with water

After purification, cooling, pressing, transmission process, parts of the gas water precipitation, another part of the water droplets shape machinery exists in the form of water and gas saturation in the locations of the gas.

1.2.3Gas station wastewater containing phenol

Gas purification, cooling, pressure, delivery process, carrying out the water in the coal tar, gas cooler place between condensate and gas drainage, gas pipeline pressure machine condensate gas station is made up of wastewater containing phenol.

1.3Gas station output of wastewater containing phenol

Gas station yield and gasification of coal water content of wastewater containing phenol, gasification agent saturation temperature control, fire detecting DaQian, gas, water vapor flux into the time the final cooling temperature, gas delivery pressure and gas transport distance and orientation, etc, but also related to the rate of gasification of coal and gas, because the higher the rate of producing gas, by gas into the gas point of saturated water and water machine, the condensation of phenol wastewater quantity is less.Gas station, for example, as shown in figure 1 of the environmental protection and energy saving process, coal gas at a rate of 3 nm3 / kg coal, coal gasification with water content is 15%, the saturation temperature and fire detecting DaQian are normal control, gas temperature of 40 ℃, eventually the gas pressure is 10000 pa, gas for straight line transportation, transportation distance is 300 m, the environment temperature of 30 ℃, at this point, the gas station gasification coal produced per ton waste water containing phenol is about 160 kg.

1.4 Gas station main pollutants wastewater containing phenol

Gas station by phenolic wastewater containing phenol, oil, suspended solids, etc, including phenol is given priority to with one yuan of phenol, with phenol content in the highest, followed by methyl phenol, between two period of a coal gasification in the furnace coal gas station as an example, the gas containing phenol wastewater PH is commonly 7 to 8.5, the main pollutant indexes such as table 1.

table1The gas containing phenol wastewater pollutants index

Table1 the contaminant index of phenol water

|

pollutants |

Index/(mg/l) |

|

Volatile phenol |

2128 |

|

oil |

2203 |

|

COD |

5520 |

|

Suspended solids |

1015 |

2The gas station treatment of wastewater containing phenol【1, 2, 3】

2.1Pretreatment of wastewater containing phenol

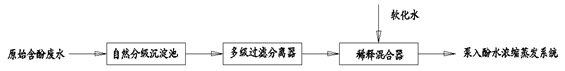

Pretreatment method has been used in the gas station, about natural sedimentation separation, mechanical filtration, chemical coagulation precipitation, electrolytic flotation method, centrifugal separation, adsorption, acid demulsification tar slag pressurized dissolved air flotation, jet float several methods such as gas, evaporation enrichment process governance gas station technology of wastewater containing phenol, phenol wastewater pretreatment, use natural sedimentation separation method, multilevel mechanical filter and the method of dilution water injection method, its process flow shown in figure 2, the water injection diluted water injection to balance the system of evaporation for the principle, main pollutants such as wastewater containing phenol after pretreatment in table 2.

figure2Pretreatment technological process of wastewater containing phenol

Chart2 process flow of phenol water pretreatment

table2After pretreatment of gas containing phenol wastewater pollution index

Table2 the contaminant index of phenol water after pretreatment

|

pollutants |

Index/(mg/l) |

|

Volatile phenol |

1308 |

|

oil |

1020 |

|

COD |

2715 |

|

Suspended solids |

85 |

2.2Eventually governance of wastewater containing phenol

2.2.1Enrichment of evaporation

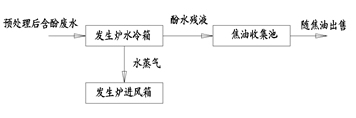

Will after pretreatment of phenol waste water pump into the water cold box of producer gas generator, relying on the part of the gas sensible heat will waste water vaporization, part of the low boiling point in the benzene wastewater containing phenol, phenol substance with vaporization, the vaporization benzene, phenol containing low boiling point substances after the water vapor flux of steam into the bottom as the gasification agent application, furnace oxidation layer temperature in 1100-1200 ℃ or so commonly, benzene, phenol content was under the temperature cracking into water and carbon dioxide.Most of the high boiling point of benzene, phenol substance has not been vaporization, water as the cold box regularly drainage, to the tar pit, waiting for the next stage.

2.2.2Ultimate dephenolizing process

High concentration phenol tar residual liquid is collected in the pool, mixed with coal tar, coal tar can be used as refining benzene, phenol and other chemical raw materials, with the residual liquid of benzene, phenol wastewater containing phenol material improves the utilization value of tar.Tar can also be used as a fuel, at this point, with the residual liquid of benzene, phenol wastewater containing phenol with toxic substances such as tar combustion, under the condition of 1100-1200 ℃, cracking of H2O and CO2 back into the atmosphere, the main reaction equations for C6H5OH CO2 + o2 = 6, 7 + 3 H2O.Two paragraphs furnace gas station evaporation concentration wastewater containing phenol final governance process as shown in figure 3.

figure3Evaporation concentration wastewater containing phenol final governance process

Chart 3 final process flow of evaporation condensing method to deal with phenol water

3The gas station related problem analysis of the governance of wastewater containing phenol

3.1The governance effect of wastewater containing phenol

Gas station containing phenol wastewater containing phenol concentration is low, unfavorable and direct recovery of benzene, phenol, combining with the characteristics of the gas occurrence boiler gasification reaction, using evaporation concentration method for treatment of wastewater containing phenol, both the use of the water in the waste water containing phenol, and completed the phenol solution concentration, and extracted by professional chemical plant, the process fully reflected the concept of governance waste recycling, and effectively implement the gas station's energy saving and emission reduction, has a remarkable economic and environmental benefits.

3.2Equipment fouling problem[4】

For the cooling process of condensate gas, wastewater containing phenol or not hard scale formed on the inner wall of the box;After pretreatment of oil and suspended solids in the wastewater containing phenol content is less, oil to light oil, suspended particle size small, both in the water is not easy to deposit, and the discharge of pollutants by regular homework system, also can effectively avoid the formation of dirt.

3.3Equipment corrosion problems[4, 5】

Evaporation and concentration system is fully enclosed, waste water and waste water of dissolved oxygen is limited, thus effectively avoid the electrochemical corrosion caused by dissolved oxygen;Evaporation and concentration process waste water temperature is higher, no microorganisms, bacteria and algae live in water, there is no corrosion caused by microbes;Wastewater containing phenol content of chlorine ion and sulfate ion itself is very low, wastewater pretreatment process, not add any treatment reagent, not increase harmful salt ions such as chloride, sulfuric acid root ion, evaporation and concentration in the process of waste water, harmful ions caused by corrosion is very small;Two paragraphs furnace gas station phenol wastewater PH is in commonly between 7-9, less subject to erosion.

4The epilogue

Gas station treatment of wastewater containing phenol, has been plagued producer gas development and application of primary environmental problem, evaporation and concentration wastewater containing phenol using gas sensible heat, waste heat recovery, waste water recycling and phenol wastewater treatment technology is able to organic combine, and the content of phenolic wastewater to resource-oriented utilization, effectively implements the gas station's energy saving and emission reduction, has a more significant economic and social benefits. |